Critical environments, clean rooms, and controlled areas should be protected within manufacturing facilities to minimize the presence of viable and non-viable contamination during manufacturing. Disposable tacky mats and sticky mats are often the go-to for floor-level contamination control. However, there are many reasons to suggest that these so-called solutions are causing more problems than they are solving.

1. Size matters

The average size of a sticky mat is 3′ x 3′ and is not large enough to thoroughly decontaminate shoes and wheels. The average human stride is 2.2’ shoes, meaning that personnel can unknowingly step directly over the mat and miss decontaminating entirely.

Lack of surface area is an issue with sticky mats, and it is often suggested that you gang them together. Meaning to ensure decontamination, multiple mats are placed next to each other to create a larger surface area. In areas that are sensitive to microbial contamination, ganging mats together can pose a new problem as contamination, microbes, and other potentially harmful particulate is given the opportunity to build up between, around, and under the mats.

2. Not an a-peeling solution

When removing the contaminated layer of a sticky mat, an average of 125,000 particles are released back into the environment, re-contaminating the area.

The performance of the sticky mats is also greatly reduced with overstrikes. Overstriking is when the same area of the mat is used multiple times to decontaminate the sole of a shoe. This is compared with an increase of up to 381.9% of contamination falling back onto the shoes when using sticky mats.

In tests comparing disposable tacky mats with polymeric flooring, there is a significantly higher reduction in not only the particulate count that is removed but also a reduction in the microbial count for both wheel and shoe contamination after contact with polymeric flooring.

3. Imperfect and impractical

To achieve the sticky mat’s optimum 27% effectiveness they need to be peeled after every use. The sticky surface of sticky mats contains an added adhesive that can pull and rip overshoes causing a tripping hazard.

Sticky mats can pose numerous difficulties with wheeled traffic as they are prone to wrapping around wheels. You might be asking yourself, is it even possible for sticky mats to fully decontaminate wheels? Studies show that it takes three full wheel rotations to effectively remove the contamination from wheel traffic. Sticky mats only have a surface area of approximately 60 inches, which is smaller than the width of most wheeled machinery.

4. Waste from disposable tacky mats

Every time you peel off the contaminated layer of a tacky mat, you create an 8-inch ball of contaminated waste. Meaning that once you have finished using a sticky mat and hopefully decontaminating shoes when entering your controlled environment, you are left with the costly and unsustainable problem of disposing of these plastic mats.

The added disposal cost for the mats as contaminated waste is not to be ignored. Sticky mats are classed as secondary waste and create an abundance of non-recyclable and unsustainable waste.

Get out of your sticky situation

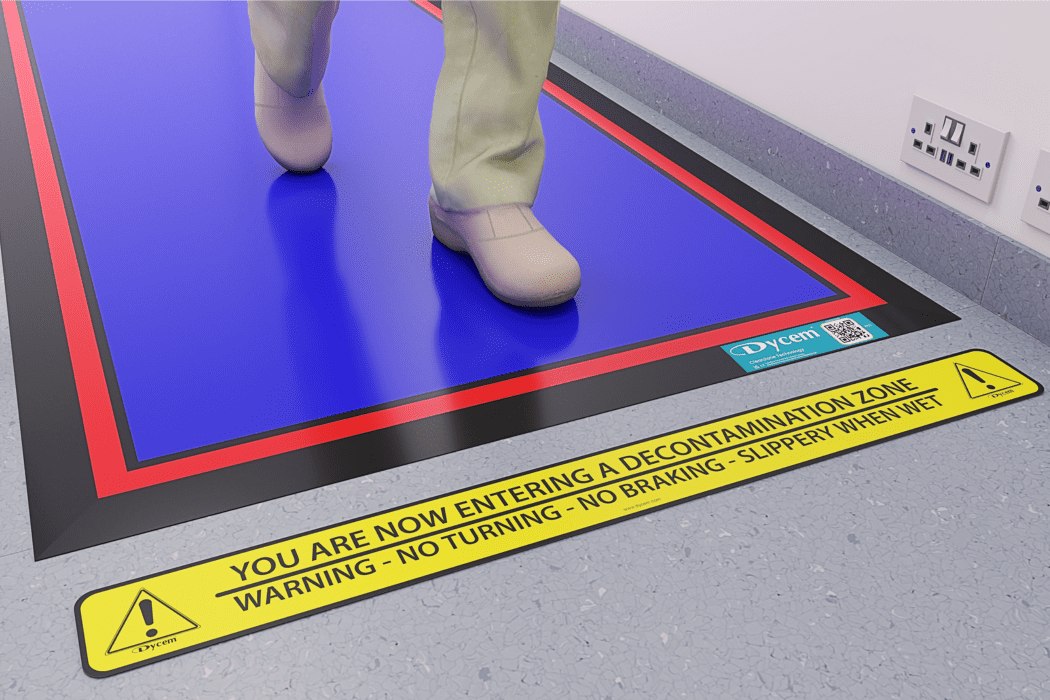

Dycem flooring and mats offer a solution to your contamination control headaches that sticky mats cannot offer.

Dycem offers completely customizable sizes, specifically allowing for six-foot falls or three full-wheel rotations to remove up to 99.9% of contamination.

The polymeric surface creates a natural tack with short-range electromagnetic forces to attract and retain the contamination. Dycem helps to reduce electrostatic discharge, due to having a surface resistivity of 108 ohms.

Dycem mats are supple to conform to shoe and wheel profiles, allowing for the collection of particles between 1 – 100 microns.

Microbial decontamination is important, and we incorporate BioMaster, a silver-ion-based antimicrobial additive proven to protect against microorganisms.